Tutorials in this section:

The P-N junction can be used for a large variety of functions other than just the basic amplifying, switching, and rectifying operations in electronic circuits. When certain materials are used for the P and N regions, a device can be constructed in such a way that will allow electricity to be generated by the junction area when exposed to a light source. These are known as photovoltaic cells, and are commonly used in solar applications. The reverse effect can also take place, where the forward biased current through a junction can be used to generate light. This phenomenon is the topic of this article, and it is the method used in light emitting diodes (LEDs).

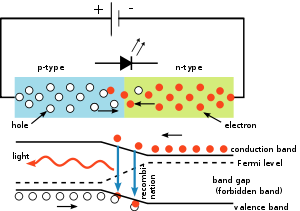

In reviewing the principles of the P-N junction, it should be noted that a depletion region exists in the junction area when no voltage is applied. There is a small potential barrier across the junction with the N side positive relative to the P side. This potential barrier prevents the excess free electrons on the N side from diffusing into the P side, and likewise for holes on the P side from diffusing into the N side. A positive voltage will have to be applied to the P side to at least the voltage level of this barrier to remove the depletion region and allow the free conduction of holes and electrons though the P-N junction. This is the basic operation for a forward biased diode.

LEDs are similar to diodes, except they are constructed with special materials for emitting light, and will have a forward bias voltage drop that is a little higher than regular diodes because of the extra voltage needed to overcome the potential barrier. This voltage could be anywhere from about 1.4 volts to over 3 volts, depending on the color. Once the forward bias voltage has been reached, a current limiting resistor should be connected to prevent damage to the LED due to high currents. A forward current of 20 mA to 40 mA is a good operating range for LEDs.

Also because of their unique materials, LEDs have a much lower reverse breakdown voltage ratings than ordinary diodes. A typical LED might only be rated at only 5 volts in reverse-bias mode. Sometimes a rectifying diode is placed in parallel or series to prevent the reverse breakdown in the LED. Unlike light bulbs, LEDs rarely burn out unless their current limit is exceeded.

When the applied voltage is sufficient to allow current to flow, the LED current is primarily due to the flow of electrons into the P side. This is because electrons are the minority carriers in the P-side, and it is not doped as heavy as the N side, were the holes are the minority carriers. The depletion region extends deeper into the P side with no voltage applied.

As electrons are now injected into the P side, they immediately recombine with the available holes. As an electron is combined with a hole, there is energy released in the form of a photon of light, because of the principle of the conservation of energy. This phenomenon is known as injection electroluminescence.

The reader may wonder why there is light emitted from an LED, but no light coming from other P-N junction devices, like diodes. This is because a photon can be emitted with direct recombination, but not with indirect recombination. LEDs are constructed with materials that allow direct recombination, such as gallium arsenide phosphide, which is a direct band gap material. Other devices use materials like silicon and germanium, where the recombination is indirect, and are indirect band gap materials.

In direct band gap materials, the minimum energy of the conduction band hovers directly over the maximum energy of the valence band in momentum space energy. This allows free electrons at the bottom of the conduction band can to directly combine with the free holes at the top of the valence band, since the momentum of the two particles are equal. The energy released in this transition results in photon emission.

In indirect band gap materials, the minimum energy in the conduction band is shifted relative to the maximum energy of the valence band. The probability of direct electron-hole recombination is much less in these materials because the momentum is different between the two particles. In order for recombination to take place, impurities are added to these materials that would provide the momentum shift needed for recombination. These impurities create donor states that can accept free electrons so a transition can take place. In order to satisfy the principle of the conservation of energy and momentum, energy must be released here also, but not in the form of a photon. Usually, this extra energy is released as heat or vibration. Because there is a slight probability of direct electron-hole recombination in indirect band gap materials, some light is emitted even in standard diodes.

When using direct band gap material, the wavelength characteristic of the emitted light (colors) is determined by the band gap energy of the materials forming the P-N junction. The LED emits light at a very small bandwidth because of the unique band gap energy of the semiconductors used. Wavelength is related to the energy band gap by the equation λ = hc/ Eg, where h is Plank’s constant, c is the speed of the light and Eg is the energy band gap.

Although many colors are available, red and infra-red are by far the most common colors emitted. According to the equation above, a material with a 2 eV band-gap would emit light at about 620 nm, which is red. Red LEDs are usually made from a combination of the elements gallium, arsenic, and phosphorus (called gallium-arsenide-phosphide), and are very common.

In fact, almost all photon-emitting (direct band gap) P-N junctions are usually based on a mixture of Group III and Group V elements, such as gallium, arsenic, phosphorous, indium, and aluminum. Silicon carbide and gallium nitride are now often used to form blue-emitting diodes, which can be combined with other colors or secondary phosphors to produce LEDs that emit white light.

Many different colors may be obtained by altering the chemical composition of the PN junction. It is also possible to combine two or more primary-color (red, green, and blue) LEDs together create additional colors. The LED combination can be mounted in the same package, and share the same optical lens. For example, a red LED can be combined with a green LED to make a yellow LED.

There are numerous advantages that LEDs offer as compared to ordinary light bulbs. The main advantage is that LEDs output far more light power per watt than an incandescent lamp, making them useful for battery operated devices. The second advantage is that LEDs are far more reliable and has a much higher service life than an incandescent lamp. This is mainly because LEDs operate at lower (cold) temperatures. This “cold” operation also allows LEDs to be turned on and off at very high speeds. LEDs are commonly used to transmit digital signal (on/off) information through empty space or other mediums like fiber-optic cable, at very high rates of speed (millions of pulses per second).

A major problem with LED design is how to keep a photon from being reabsorbed into the device after it is generated. As LEDs are usually built on an N-type substrate, with a P-type layer deposited on its surface, one solution is to make the P layer thin enough to create a depletion layer. The diffusion length can be adjusted according to the equation: L = √ Dτ, where L is the diffusion length, D is the diffusion coefficient and τ is the carrier life time. When increased beyond a critical length, there is a high probability of re-absorption of the photons into the device. Another method is to increase doping concentration of the substrate near the surface, so that the recombination of minority charge carriers and light emission can occur right at the surface of the material.

If a photon is emitted in a direction that is perpendicular to the material’s surface, there is almost a sure chance that photon will escape without being reabsorbed. When the angle of the photon’s path and the surface is increased beyond a certain point, there is almost zero probability of escaping. So some LEDs have a “jewel” type structure to minimize reabsorbing. (If a photon was generated in the center of a sphere, there is almost 100% chance of it not being reabsorbed.)

It is well known that a semiconductor becomes more conductive through the absorption of electromagnetic radiation, such as visible light or infra-red. The characteristics of an LED can be reversed so that they can be used as light-sensing devices (photodiodes), where the resistance is a function of light intensity. They can even generate a small voltage when exposed to light, like a solar cell on a small scale. If the light absorbed by a semiconductor has energy higher than the band gap (Eg) electrons are able to jump from the valence to the conduction band, which will increase the electrical conductivity of the semiconductor. The empty spot left by the electron in the valence band (hole) can then be occupied by another electron in the valance band, which then becomes a source of hole conductivity.

The LEDs discussed in this article have been the inorganic type. A new type of LED, the organic LED (OLED), has recently been developed. The physics of operation for OLEDs is the same as inorganic ones, but its design is quite different, as they use additional layers of material. OLEDs can offer several advantages over LEDs, such as increased viewing angle, brightness, contrast, and resolution.